Short Communication - (2025) Volume 12, Issue 1

Static Progressive Orthosis for Gradual Correction/Prevention of Contractures of Elbow Joint by Use of Elbow Lock Mechanism

Lukeshkumar R. Bhuyar* and

Ansari Aisha Siddiqua Iqbal Ahmed

Department of Prosthetics and Orthotics, All India Institute of Physical Medicine and Rehabilitation, Mumbai, Maharashtra, India

*Correspondence:

Lukeshkumar R. Bhuyar, Department of Prosthetics and Orthotics, All India Institute of Physical Medicine and Rehabilitation, Mumbai, Maharashtra,

India,

Email:

Received: 19-Jul-2023, Manuscript No. IPBJR-24-17056;

Editor assigned: 21-Jul-2023, Pre QC No. IPBJR-24-17056 (PQ);

Reviewed: 03-Aug-2023, QC No. IPBJR-24-17056;

Revised: 14-Jan-2025, Manuscript No. IPBJR-24-17056 (R);

Published:

21-Jan-2025, DOI: 10.36648/2394-3718.12.1.116

Abstract

Background: Currently, there are two types of interventions for elbow contracture: Operative and non-operative treatment. The operative treatment involves open or arthroscopic release, arthroplasty, and manipulation under anesthesia. The non-operative treatment mainly involves passive or assistant movement, continuous passive movement, serial bracing, and static and dynamic orthosis. The newly designed static progressive orthosis for gradual correction/prevention of contractures by the use of an elbow joint lock. The elbow joint is made such that it locks at different desirable angles to correct or prevent the contracture.

It is presented in this report which helps to improve the range of motion of the joint without using serial casting method. The mechanisms of static progressive orthosis for contracture is based on creep and stress relaxation. As one of the most common musculoskeletal complications following trauma, elbow contracture is a frequent source of disabled daily activities. Conventional interventions are inadequate to provide favorable outcome. The static progressive orthosis are getting popular in the treatment of this problem. Serial casting method is very time consuming and it requires removal and change after sometime to be kept in another angle for correction.

The new concept of elbow joint which locks at every desired angles and helps to improve the range of motion in stiff elbow joint and contractures following trauma is useful for gradual correction/ prevention of contractures in elbow joint.

Aims: The available design in the market provides gradual intervals but not less than 5 degrees of intervals. Here we aim to provide gradual correction at less than 5 degrees of intervals.

Methods: The static progressive orthosis with newly designed elbow joint lock is an attempt to introduce a new concept of the elbow joint for gradual correction/ prevention of contractures of elbow joint following trauma, musculoskeletal injuries, congenital contractures, etc.

Objectives:

• Introduction of a new elbow joint lock for elbow contractures.

• Overcoming the issues with previous designs and methods to correct or prevent contractures.

• Achieving a more normal and anatomical Range of motion using simple mechanism.

Keywords

Orthosis; Elbow contracture; Anesthesia; Mechanism; Treatment

Introduction

Elbow stiffness with loss of function is a common disabling problem that usually arises as a complication of trauma, but may also occur following burns or head injury or in association with degenerative, inflammatory or haemophiliac arthropathy and congenital malformations. The degree of stiffness is related to the severity of the injury and the duration of immobilisation at initial treatment [1].

Elbow contractures can be classified as extrinsic or intrinsic according to the underlying aetiology. Extrinsic contractures involve the peri-articular soft-tissues with a normal or near normal articular surface. Intrinsic factors include disruption of the normal articular surface, osteophytes, intra-articular loose bodies and secondary osteoarthritis [2].

Generally, the functional range of motion for the elbow is between 30 to 130 deg. Flexion contractures greater than 45 deg will significantly limit ADLs. In general, contractures are the result of constriction or stiffness of connective tissues. Aside from joints (such as the elbows), this can also affect the skin, ligaments, muscles, and tendons [3].

Materials and Methods

Components

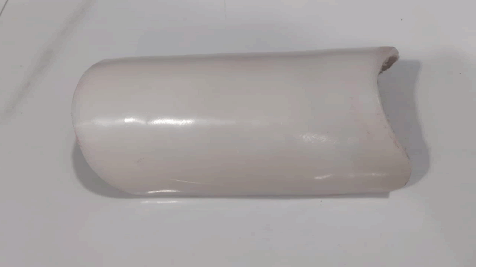

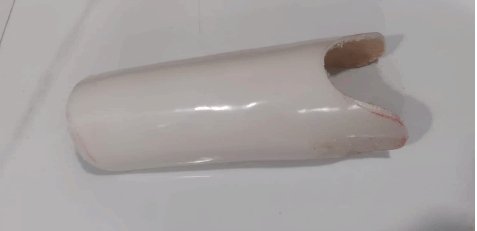

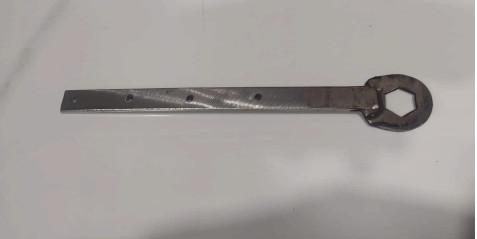

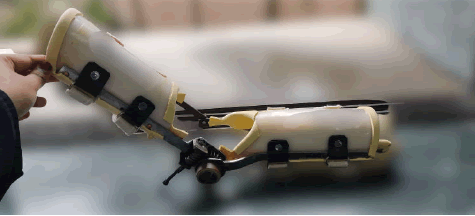

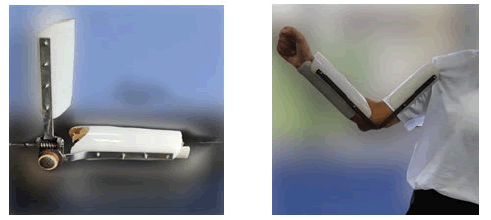

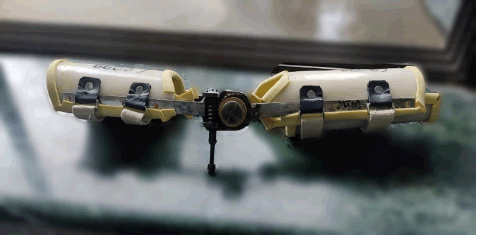

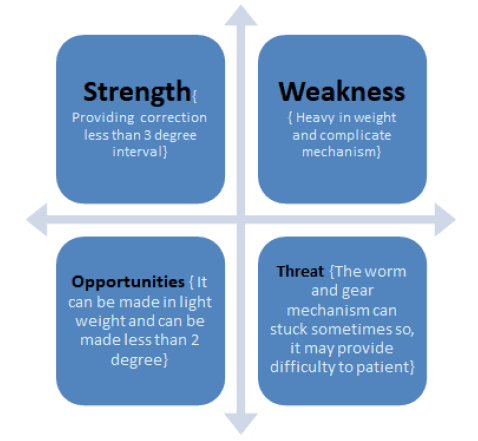

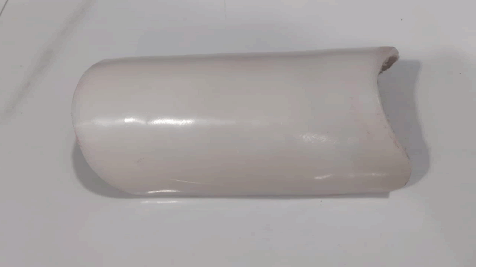

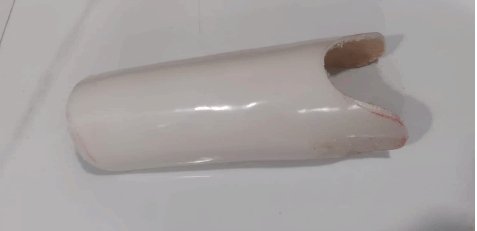

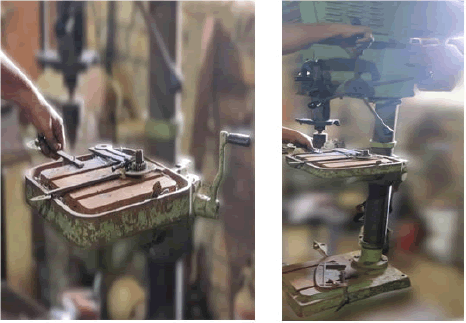

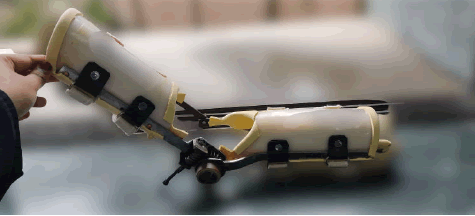

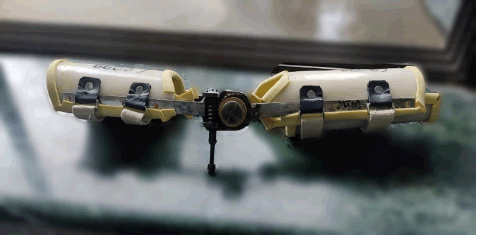

This design consists of 1) Arm shell; 2) Antero-posterior enclosed forearm shell; 3) Elbow joint with lock mechanism; 4) Uprights (Figures 1-4).

Figure 1: Arm shell.

Figure 2: Forearm shell.

Figure 3: Elbow lock mechanism.

Figure 4: Elbow joint lock mechanism.

Fabrication

Measurement: Linear measurement:

Proximal 1/3rd of humerus to elbow joint proximal 1/3rd to ½ inch above styloid process.

Circumference:

• Maximum arm circumference.

• Minimum arm circumference.

• Max forearm circumference.

• Min forearm circumference.

• Across elbow joint.

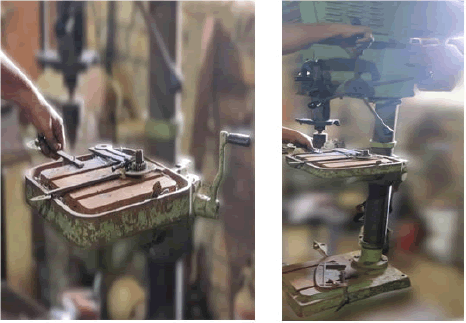

First of all, an arm shell mold and forearm shell mold were prepared by taking cast of the patient [4]. Then the next step is to cut HDPE sheet according to measurement of arm and kept in oven at 120-150 degree temperature. As the sheet melts it is molded on the arm mold and proper shape of arm is provided. Similarly same procedure is followed for fabrication of forearm shell. Now mark the trimlines and cut accordingly. Finishing is done and smoothens so that it does not hurt patient. Now, the elbow joint with lock which consists of worm and gear mechanism to lock at different desirable angles is attached to the forearm shell and arm shell with the help of uprights [5]. Similarly on opposite sides uprights are attached for simultaneous movement (Figures 5 and 6).

Figure 5: Gear.

Figure 6: Making of elbow joint.

Working of Model

The elbow joint with lock is made such that when the patients’ hand has to be kept in 10 degree of flexion it will be locked in that position and will not change its position until and unless the worm is not moved manually or with Allen key of 4 mm [6].

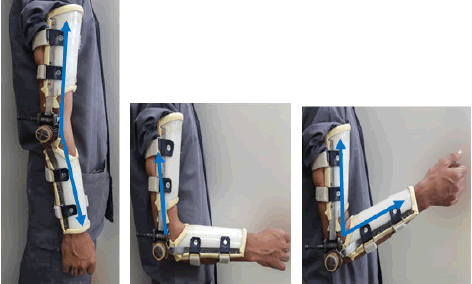

As in static progressive therapy of patient of elbow contracture gradually correction is provided by increase in degree of motion of elbow flexion.

Using static progressive orthoses, the tissue is stretched and held at a constant length. The amount of force is decreased over time. It is a periodic application of stress relaxation that is experienced. Static progressive orthoses are typically worn in 30 minutes 2-3 times a day [7]. In each 30 minute session the force that is being applied is increased every 5-10 minutes by the patient in an effort to increase ROM during the time the brace is being worn [8]. This treatment usually lasts about 2-4 months.

The uprights which contain the gear and worm mechanism are attached to arm shell at two points.

The upright which is movable is attached to forearm shell and moves throughout the range of motion and locks at desirable angle. In stress relaxation, the displacement is constant and the applied force varies [9]. This is the principle of static progressive orthoses, in which patients are instructed to constantly adjust and readjust the tension on their stiff joints [10]. The tissue reaches the plastic deformation state more quickly and the effects.

• Non-elastic component places tension on stiff joint/tissue to hold at its maximum tolerable length.

• Adjustments to the tension on each point can be made by the client.

• The orthotic design maintains the shortened tissue at its maximal tolerable length and does not stress beyond it. It is very important not to exceed the maximal tolerable stress level, which could lead to tissue failure.

• The longer the tissues remain at its maximum tolerable length, the more it increases in length. This concept is known as Total End Range Time (TERT).

• Success can be measured by small gains of perhaps 5–10 degrees a week.

Results and Discussion

• Improved range of motion without pain; high tolerance for orthotic use because the patient can control the force of the tension; higher compliance and higher patient satisfaction result [11].

• The patient is able to adjust the tension force gradually, as this type of orthotic intervention takes advantage of small incremental changes in tissue length.

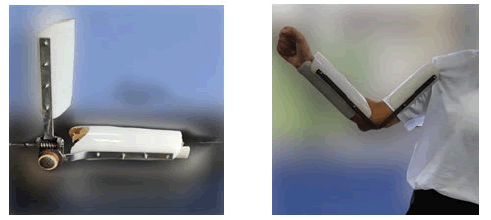

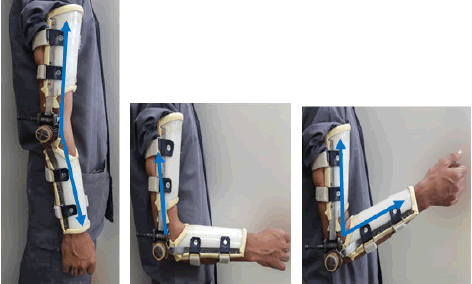

• The optimum orthotic design allows for small changes in joint motion without remolding of the orthosis each time gains in range of motion are accomplished (Figures 7-11).

Figure 7: Final design.

Figure 8: Prototype.

Figure 9: Side view of orthosis. Figure

Figure 10: Changing of angle at regular interval.

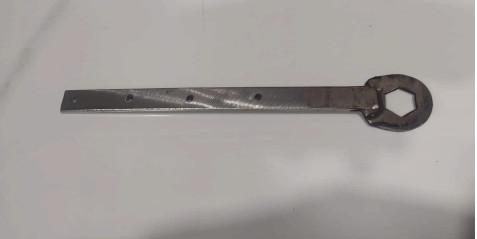

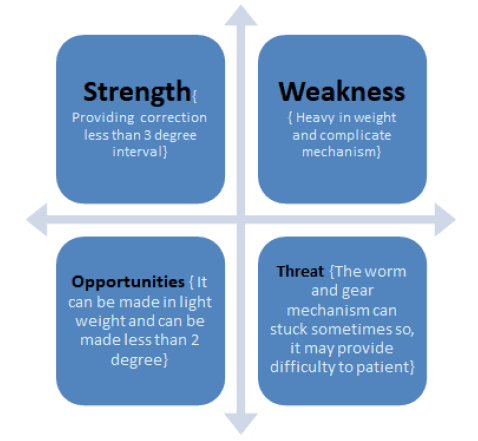

Figure 11: SWOT analysis.

Conclusion

As this design is conceptual and no trials are yet been done, it becomes premature to comment upon the actual success of the design. But as the design is the result of detailed study of human elbow joint and mechanics, and stimulates the same.

The desired advantages as well as the listed drawbacks are expected in the working model of the static progressive orthosis with elbow joint lock for gradual correction/ prevention of elbow contractures by improving the range of motion.

The newly designed static progressive orthosis with elbow joint lock is useful in increasing the range of motion of stiff elbow joint by gradually increasing the desired flexionextension angle and locking at that desired angle.

Acknowledgement

In the current scientific realm, no research is ever carried out in solitude. This thesis would not have been possible without the encouragement and support of many individuals to whom I owe my deepest gratitude.

First and foremost, I would like to thank Dr. Anil Kumar Gaur, Director, All India Institute of Physical Medicine and Rehabilitation who permitted me to carry out this study in the institute.

I would like to thank Mr. Deepak Prabhu, Head of Department of Prosthetics and Orthotics for his encouragement and advice in the subject concerned.

References

- BD Chaurasia's (2019) Human anatomy, volume 1: Regional and applied dissection and clinical: Upper limb and thorax. 8th edition; CBS Publishers and Distributors; 2019:372.

- Nordin M, Frankel VH (2001) Basic biomechanics of the musculoskeletal system. Lippincott Williams and Wilkins; 467.

- Hsu JD, Michael J, Fisk J (2008) AAOS Atlas of orthoses and assistive devices e-book. 4th Edition. Elsevier Health Sciences.

- Chen B, Lin J, Liu L, Niu W (2017) Static progressive orthoses for elbow contracture: A systematic review. J Health Eng. 2017(1):7498094.

[Crossref] [Google Scholar] [PubMed]

- Veltman ES, Doornberg JN, Eygendaal D, van den Bekerom MP (2015) Static progressive versus dynamic splinting for posttraumatic elbow stiffness: A systematic review of 232 patients. Arch Orthop Trauma Surg. 35:613-617.

[Crossref] [Google Scholar] [PubMed]

- Grenier ML, Chinchalkar SJ, Pipicelli JG (2012) Static progressive orthosis for patients with limited radial and/or ulnar deviation: An innovative orthotic design. J Hand Ther. 25(4):425-429.

[Crossref] [Google Scholar] [PubMed]

- Bai Z, Shu T, Hao Y, Niu W (2019) An alternative static progressive orthosis for forearm pronation and supination. J Hand Ther. 32(3):403-406.

[Crossref] [Google Scholar] [PubMed]

- Ulrich SD, Bonutti PM, Seyler TM, Marker DR, Morrey BF, et al. (2010) Restoring range of motion via stress relaxation and static progressive stretch in post-traumatic elbow contractures. J Shoulder Elbow Surg. 19(2):196-201.

[Crossref] [Google Scholar] [PubMed]

- Sim G, Fleming J, Glasgow C (2021) Mobilizing orthoses in the management of post-traumatic elbow contractures: A survey of Australian hand therapy practice. J Hand Ther. 34(1):90-99.

[Crossref] [Google Scholar] [PubMed]

- Grenier ML, Shankland B (2020) The use of static progressive and serial static orthoses in the management of elbow contractures after complex fracture dislocation injuries: A pediatric case study. J Hand Ther. 33(1):127-133.

[Crossref] [Google Scholar] [PubMed]

- Chinchalkar SJ, Pearce J, Athwal GS (2009) Static progressive versus three-point elbow extension splinting: A mathematical analysis. J Hand Ther. 22(1):37-43.

[Crossref] [Google Scholar] [PubMed]

Citation: Bhuyar LR, Iqbal Ahmed AAS (2025) Static Progressive Orthosis for Gradual Correction/Prevention of Contractures

of Elbow Joint by Use of Elbow Lock Mechanism. Br J Res. 12:116.

Copyright: © 2025 Bhuyar LR, et al. This is an open-access article distributed under the terms of the Creative

Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the

original author and source are credited.