Review Article - (2025) Volume 12, Issue 1

Use of Plant Extracts in Peanut Oil to Improve Nutritional Value and Antioxidant Activity: A Review

Peter Sarpong*

Department of Food Science and Technology, University for Development Studies, Tamale, Ghana

*Correspondence:

Peter Sarpong, Department of Food Science and Technology, University for Development Studies, Tamale,

Ghana,

Email:

Received: 09-May-2024, Manuscript No. IPBJR-24-19805;

Editor assigned: 14-May-2024, Pre QC No. IPBJR-24-19805 (PQ);

Reviewed: 28-May-2024, QC No. IPBJR-24-19805;

Revised: 03-Jan-2025, Manuscript No. IPBJR-24-19805 (R);

Published:

10-Jan-2025, DOI: 10.35841/2394-3718-12.01.119

Abstract

This review examines the potential of using plant extracts to improve peanut oil’s nutritional value and antioxidant properties. Peanut Oil (PO) is high in unsaturated fats and vitamin E. However, the oil can undergo oxidation, which may lead to the development of harmful compounds and loss of nutrients. The edible oils industry utilizes synthetic and natural antioxidants to improve the oxidative stability of bulk edible oils. Many efforts are being undertaken to identify a safe and effective alternative to BHA, BHT and TBHQ. Plant extracts (e.g., phenolics, flavonoids, carotenoids) from canola meal, rosemary, sage, thyme and sumac, possess antioxidant and anti-inflammatory properties contributing to PO’s stability. Many plant extracts have been studied in PO, including those derived from herbs, spices, fruits and vegetables. Several studies have demonstrated that these extracts can upsurge PO’s shelf life and nutritive value through increased antioxidant activity and reduced lipid oxidation. Several plant extracts possess antimicrobial and anticancer properties, which may further enhance the health benefits of PO. Plant extracts can also negatively impact PO’s sensory properties and stability. Consequently, plant extracts should be carefully selected, and extraction and processing methods should be optimized to produce the desired effects without compromising oil quality.

Keywords

Plant extracts; Peanut oil; Nutritional enhancement; Antioxidant activity; Health benefits

Introduction

Peanuts (Arachis hypogaea), also known as groundnuts, play a crucial role in agriculture. The vast majority of peanut production worldwide is utilized for oil extraction, and most of this production is consumed in the Asian subcontinent, particularly in India. PO production has expanded globally from 5.47 million metric tons in 2013 to 6.48 million in 2022, with China on top of the table. Several peanut cultivars are available on the market; however, four fundamental kinds (Runner, Spanish, Virginia and Valencia) have emerged as the most popular because of their taste, size, oil content, form and disease resistance [1].

It is currently estimated that peanuts contain more proteins, fats, fibre, vitamins and carbohydrates than any other type of nut. They are readily available and reasonably priced compared to other nuts worldwide [2]. Most developed countries use peanuts for confectionery products, peanut butter, snacks and oil production. Most peanuts grown in the United States are processed into snack bars, peanut butter and salted peanuts. The results of epidemiological research have indicated that peanut consumption is connected to a lower risk of gallstones, cardiac disease and diabetes in both sexes. Several additional health benefits, including lower obesity, hypertension, cancer and inflammation, have been observed with limited proof [3].

PO is ample in vitamin E and unsaturated fatty acids, contributing to its wide variety of use [4]. However, the oil can be oxidized; causing harmful compounds to form that adversely affect its nutritional value and shelf life. Antioxidants are derived chiefly from byproducts of vegetable and fruit processing and are used to ensure the stability of oil during storage and food processing. Some plant parts, such as kernels, leaves, peels, flowers and roots, which are unwanted products or byproducts, contain antioxidant compounds that have been proven to improve human health [5]. PO has been investigated to improve its antioxidant effectiveness, including using plant extracts. Mishra et al., found that plant extracts were rich sources of constituents, including flavonoids, phenolic and carotenoids, which could enhance peanut oil’s stability and nutritional quality.

As such, this review discusses the utilization of plant extracts in peanut oil to improve its nutritional value and antioxidant activity. It also examines some plant extracts used in research, their mode of action and the challenges that they pose. Furthermore, the study discusses the potential health benefits of peanut oil plant extracts and the need for further research in this area.

Literature Review

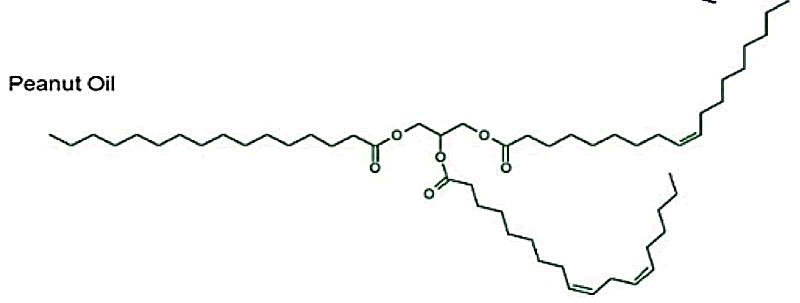

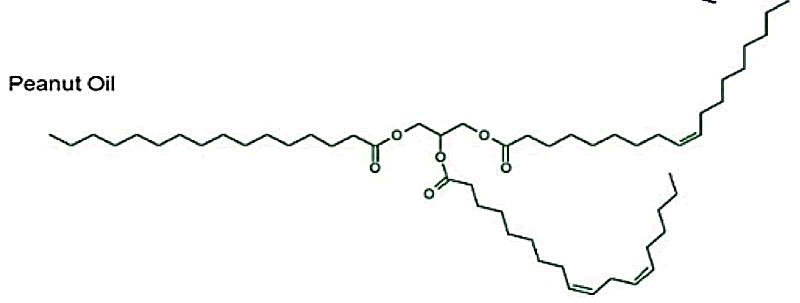

Peanuts contain 47%-50% of oils. Peanut oil (Figure 1) has a yellowish color and a nutty and roasted flavor.

Figure 1: Chemical structure of peanut oil.

It contains natural bioactive compounds, such as tocotrienols, tocopherols, phytosterols and squalene, which correlate to its nutritional and health advantages. The concentration of these bioactive minor constituents differs with variety, weather patterns, crop year, maturation process and storage conditions [6]. The fatty acid composition influences the nutrient content, physical characteristics and the oil’s shelf life [7]. Tocols (tocotrienols and tocopherols) are vitamin E derivatives. Their antioxidant and vitamin activity helps protect vitamin A, essential fatty acids, and β-carotene. Phytosterols have various beneficial properties, including antioxidant action, antitumor and anti-inflammatory, anticancer and the potential to reduce LDL cholesterols and plasma. Squalene (structurally akin to β- carotene) has anticancer and tumour-inhibitory effects, antioxidant characteristics and is thought to be effective in lowering cholesterol and triglycerides [8]. A phytosterol, a plant sterol, is synthesized from squalene. This compound is structurally and functionally similar to cholesterol. The polyunsaturated and monounsaturated fatty acids in peanut oil may reduce cardiovascular disease. Moreover, it contains vitamin E, an antioxidant that prevents cells from being damaged by oxidation [9]. Peanut oil also has low levels of saturated fats, which promote cardiovascular disease risk. Its oxidative susceptibility, however, suggests a need to enhance and stabilize its shelf life.

Physico-chemical Characteristics of Peanut Oil

Oils and fats are characterized by their composition of fatty acids and their location within the Triacylglycerol (TAG) molecular structure. Oil extracted from peanut kernels is known for its pale yellow color and distinctively nutty flavor and smell. Oil may lose its odor during refining [10]. The oil is rich in oleic acid, contributing to its excellent stability against oxidation and freezing. PO is considered non-drying and solidifies between 0 and 3°C. As a result of refinement, refined oil is free from aflatoxins, a group of carcinogenic substances linked to proteins. However, crude or minimally processed oil may contain certain levels of aflatoxins. Table 1 shows the main chemical and physical properties of peanut oil.

| Property |

Value |

| Iodine value (Wijs) |

86-107 |

| Hehner value |

95-96 |

| Acid value (Refined) |

0.6 mg KOH/ g oil |

| 0.99 mg KOH/g oil |

| Viscosity (21.1°C) |

70.7 mPaS |

| Polenske value |

0.5 |

| Melting point of fatty acids |

22-30°C |

| Melting point |

0-3°C |

| Refractive index 40°C |

1.46-1.465 |

| 1.456 |

| Moisture and volatiles |

0.23% |

| Smoke point |

226.4°C |

| Saponification number |

187-196 |

| Color (Lovibond, Maximum) |

Yellow 16-25; 2.0 Red |

| Surface tension |

35.6 Nm/m |

| Color (Visual) |

Light yellow |

Table 1: Physicochemical characteristics of peanut oil.

Discussion

Plant Extracts as Sources of Natural Antioxidants and Bioactive Compounds

Several phytochemicals, including phenolics, flavonoids and carotenoids in plant extracts, have antioxidant and antiinflammatory properties that enhance PO’s stability and nutritive value [11]. Infusing rosemary extract into edible oils, such as rice bran, soybean and cottonseed oils, has effectively inhibited the degradation of polyunsaturated fatty acids and tocopherols. This infusion process enhanced the oils’ antioxidant capacity and total phenolic content, decreasing peroxide value and slowing oil degradation. Bioactive compounds found in plant extracts contribute to the biological function of oils. Carotenoid and lycopene compounds have recently garnered considerable interest because of their bioactive characteristics. They serve as powerful antioxidants in the human body, contributing to reducing chronic illnesses by protecting cells from oxidative destruction [12]. The carotenoids in fruits and vegetables possess anti-inflammatory and immune-enhancing abilities [13]. Phytochemicals such as carotenoids, phenolic acids, stilbenes, flavonoids, fibres and vitamins can enhance traditional foods’ nutritional value. Various fruits, including tamarind, guava, citrus and pumpkin seeds, have been used to produce extracts with antioxidant properties. Increasing oil’s oxidative stability is often achieved by using olive extracts. An olive phenolic extract has been shown to protect oils during storage and frying [14]. Carotenoids have several advantages, including antioxidant capacity and health advantages. These molecules can be extracted from various types of vegetables or waste. The abundance of biologically active compounds in aromatic plants such as oregano, rosemary, and basil are well known, including phenolics with antimicrobial, antifungal, antioxidant and anti-inflammatory activities. Sunflower oil, for instance, was enhanced with oregano extracts and canola oil, soybean oil enhancement with thyme extracts [15].

Commonly Used Plant Extracts in Peanut Oil

Plant extracts contain bioactive compounds that can boost peanut oil’s nutrient content and shelf life by acting as antioxidants and stabilizers. Various plant extracts have enhanced some vegetable oil’s stability and antioxidant activity (Table 2). The effects of Rosemary extract (4% concentration) (Rosmarinus officinalis) on PO stability has been studied. The rosemary extract contains phenolics such as rosmarinic acids, carnosic and carnosol. These compounds are antioxidants and can prevent PO from oxidizing. Similarly, grape seed extract (Vitis vinifera) has been widely used to control oxidation in PO. Several studies have indicated that grape seed extract contains proanthocyanidins, which have potent antioxidant and anti-inflammatory properties. Grape seed extract prevents PO oxidation and increases shelf life. Green tea (Camellia sinensis) extract, sage extract, sumac extract, Jackfruit seed, Polygonum cuspidatum and Cortex fraxini have also been investigated. Shyamala et al., examined the antioxidant properties of cabbage (Brassica oleracea var. capitata), hongone (Alternanthera sessilis), coriander leaves (Coriandrum sativum) and spinach (Spinacia oleracea) in PO. An African spice, Aframomum danielli, contains antioxidant extracts capable of stabilizing refined peanut oil [16]. Various solvent extracts of tamarind (Tamarindus indica L.) and lettuce (Pisonia morindifolia R. Br.) were assessed for their antioxidant abilities. Both DPPH radicals and hydroxyl radicals were shown to be scavenged by the extracts [17]. A study on peanut oils enriched with tomato peel carotenoids demonstrated higher stability than the control oils.

| Type of extract |

Concentration |

Enriched Oils |

| Tomato (Solanum lycopersicum) peel |

1%-5% |

Sunflower oil |

| Spinach (Spinacia oleracea) leaves |

2, 4 and 8 g/100 g |

Sunflower oil |

| Olive (Olea europea) leaves |

20, 40, 60, 80 and 100 µg |

Sunflower oil |

| Myrtle (Myrtus communis) leaves |

500 µL |

Extra Virgin Olive Oil |

| Goji (Lycium barbarum) berries |

1.5 mg/100 g oil, |

Extra Virgin Olive Oil |

| Crude phenolic concentrate from fresh OMWW |

400 and 600 mg/kg |

Refined olive oil |

Table 2: Various plants extracts used in vegetable oils.

Methods for Extracting and Incorporating Plant Extracts into Peanut Oil

Methods for extracting plant extracts: Various extraction procedures can be used to extract plant materials. There are two basic categories of extraction techniques: Conventional and unconventional. Extraction methods that follow conventional methods typically utilize high solvent consumption and may or may not involve heat treatment. In contrast, unconventional techniques can boost productivity and/or selectivity through processing aids and energy inputs such as pulsed electric fields, ultrasounds and supercritical fluids. Recent advances led to the development of nonconventional environmentally friendly methods since they use fewer synthetics and organic chemicals, reduce operating time, and produce a greater yield and quality of extract. However, Conventional Extraction (CE) methods, like Soxhlet, continue to be employed as a reference for comparing the success of novel techniques [18].

Non-conventional Methods

Ultrasound-Assisted Extraction (UAE): Recently, research has demonstrated the advantages of UAE over CE concerning the efficacy of extraction, lower energy utilization, and non-toxic solvents. By allowing the release of target components, ultrasonic waves damage cellular walls and create pressure and cavitation [19]. The critical physical processes involved in ultrasound extraction are diffusion over the cell wall and washing the cell contents once the cells have been ruptured [20].

A successful extraction requires consideration of several factors, including moisture content analysis, milling degree, solvent type and particle size. Additionally, the ultrasound procedure depends on temperature, pressure, frequency and duration of sonication. The choice of an appropriate solvent is crucial in the UAE because it substantially impacts cavitation efficacy and the transmission of acoustic energy to the reactants. Lupacchini et al., conducted a recent comprehensive study of UAE with or without green and nonconventional solvents. According to the report, the most often utilized solvents in the UAE include glycerol, ionic liquids, water, ethylene glycol and various biomass-based solvents.

Pulsed Electric Field (PEF): An electroporation field created by PEF has strengths from 15 and 35 kV/cm and energies ranging from 50 to 700 kJ/kg, which can electroporate cellular membranes and produce inactivation in vegetative cells. The ability of PEF to liberate intracellular molecules at a low energy cost also makes it useful for extractions, according to recent studies. However, industrial applications of PEF have been limited due to a lack of readily accessible treatment compartments and strong PEF producers. Raso et al. and Yan et al. argue that the situation has improved in recent decades. According to Soliva-Fortuny et al., moderate PEF can boost the extractability of Bioactive Compounds (BACs) from diverse foods with less energy input and can even produce new compounds in active tissues.

According to Barba et al., PEF may also boost the recovery and availability of nutrients in foods and improve osmotic dehydration, freeze-drying and solvent-assisted extraction. According to recent evaluations, PEF can be advantageous for industrial applications owing to its potential to minimize extraction time, enhance efficiency and lower processing temperature, among other benefits.

Supercritical Fluids Extraction (SFE): Materials on Earth can be classified as solid, liquid, or gas. A material can only be supercritical if heated and squeezed past its critical point. In supercritical states, gases and liquids’ characteristics disappear and cannot be liquefied by changing their temperature or pressure. As well as exhibiting gaseous characteristics such as viscosity, diffusion, and surface tension, supercritical fluids exhibit liquid characteristics such as density and solvation power. Thus, acquiring an increased yield of compounds within a short period is feasible by utilizing it for extraction.

SFE is an ecologically friendly, high-efficiency process for extracting Essential Oils (EOs) from plants. This procedure occurs at lower temperatures and in the absence of light, allowing for easier separation of the solvent and extracts.

High Pressure (HP): HP is a new non-thermal method found as ecologically benign and with substantial promise in the pharmaceutical and food sectors. Standard pressure ranges for the HP process are 100 MPa to 800 (1000) MPa. High- Pressure Assisted Extraction (HPAE) necessitates pressure levels surpassing 100 MPa, while medium-to-high pressurization techniques like Pressurized Liquid Extraction (PLE) and Pressurized Hot Water Extraction (PHWE) require a moderate pressure of approximately 10 MPa. Despite being a relatively new extraction method for isolating Bioactive Compounds (BACs) from natural sources, HPAE stands out as an up-and-coming technique due to its ability to preserve biological activity by avoiding the application of heat. Extraction is commonly accomplished at fluid pressures ranging from 100 to 1000 MPa in three stages: come-up, pressure maintenance and pressure relief.

Cellular wall, plant tissue and membrane rupture contribute to enhanced mass transfer of soluble ingredients between the materials and the solvent, facilitating bidirectional extraction. This approach significantly reduces the extraction time compared to previous methods, thanks to the rapid solubility predicted by phase behavior theory at higher pressures. During pressure maintenance, the pressure within and outside the cells is balanced, allowing the solvent to enter the cells quickly and interact with their contents, allowing the active components to dissolve in less time. The length of this stage has a direct impact on the extraction yields. Following that, the pressure relief phase, which lasts only a few seconds, causes alterations in non-covalent bonds as the pressure inside the cells rapidly drops. Membrane degradation, reduced diffusion, penetration resistance and excellent permeability result from cell expansion. After the pressure relief, the resultant mixture must be divided and filtered to get the desired extract. When compared to traditional extraction procedures, High-Pressure Assisted Extraction (HPAE) dramatically reduces the environmental impact, owing to lower energy consumption, cheaper costs and a lesser potential for ecological damage due to the absence of solvent volatilization.

Pressurized Liquid Extraction (PLE): PLE utilises the advantages of high pressure to improve the extraction process’s efficiency. The fundamental concept of Pressurized Liquid Extraction (PLE) revolves around maintaining the solvent in a liquid state at elevated pressures, exceeding its typical boiling point. The use of high pressure is critical in easing the extraction process. The increasing popularity of PLE-based techniques can be attributed to automation methods, reduced extraction time and lower solvent requirements, which have collectively contributed to improved efficiency and effectiveness in extraction processes. With PLE, a limited amount of solvent is required as high pressure and temperatures are combined to provide fast extraction. A higher temperature increases solubility and mass transfer rates, reduces surface tension and solvent viscosity and increases extraction rates.

In PLE, the average temperature typically falls within the ambient temperature to 200°C, while the applied pressure ranges from 3.5 to 20 MPa. Pressurized Hot Water Extraction (PHWE) is explicitly employed when water is utilized as the solvent in the extraction process. Because water has a lower dielectric constant at high temperatures, this causes a decrease in viscosity during extraction, lowering surface tension and increasing diffusivity qualities. PHWE may extract polar, slightly polar and non-polar substances.

Hydrodistillation

Plant extracts have traditionally been extracted via hydrodistillation, a method of extracting plant components without using organic solvents for dehydration. Hydrodistillation can be grouped into three kinds based on the process employed: (1) Water distillation, (2) Steam and water distillation and (3) Direct steam distillation. In a still compartment, plant materials are filled, water is added and the mixture is subsequently boiled. Direct steam injection is another alternative method. In plant tissues, hot water and steam influence the release of bioactive compounds. An indirect cooling agent, such as water, condenses oil and water vapour. The mixture is concentrated and then run through a separator, automatically separating oil and bioactive substances from water. The hydrodistillation process can be characterized by three key strategies, namely hydro-diffusion, thermal decomposition and hydrolysis. Some volatile components may evaporate at high extraction temperatures. One limitation of this method is its inability to extract thermolabile compounds effectively.

Microwave Assisted Extraction (MAE): Researchers have been experimenting with MAE to extract bioactive chemicals from various natural and plant materials. Microwave sources emit radiation with wavelengths ranging from 1 cm to 1 m and frequencies ranging from 300 MHz to 300 GHz. An electric and magnetic field accompanies these electromagnetic waves. A description of two perpendicular fields is provided. Originally, microwaves were used to heat items that could absorb electromagnetic energy and translate it to heat. A typical commercial microwave instrument operates at 2450 MHz and produces about 600-700 Watts of power. Recent advances have reduced the amount of bioactive chemicals lost during extraction while speeding up the process.

Consequently, microwave-assisted extraction has become highly effective, particularly in extracting medicinal plants. Furthermore, this approach has been shown to reduce the loss of target biological components during extraction. MAE has become a substitute for conventional extraction methods for antioxidants due to its capacity to decrease solvent volume and extraction time. By heating the solvent and using less solvent than conventional methods, MAE aims to extract antioxidants from plants.

Conventional Methods

The conventional extraction method has several fundamental challenges, including prolonged extraction time, high-purity solvents and prolonged extraction time for thermolabile substances. Cowan, notes that conventional extraction procedures rely on the solvent. As shown in Table 3, various solvents have been employed to extract bioactive substances.

| Water |

Dichloromethanol |

Methanol |

Ether |

Chloroform |

Ethanol |

Acetone |

| Tannins |

Terpenoids |

Terpenoids |

Terpenoids |

Flavonoids |

Tannins |

Flavonoids |

| Anthocyanins |

|

Anthocyanin |

Alkaloids |

Terpenoids |

Polyphenols |

|

| Terpenoids |

|

Tannins |

|

|

Terpenoids |

|

| Saponins |

|

Saponins |

|

|

Flavonol |

|

| |

|

Flavones |

|

|

Alkaloids |

|

| |

|

Polyphenol |

|

|

|

|

Table 3: Bioactive compounds extracted using various solvents.

Soxhlet extraction: Frequently, a thimble is used to hold the dried sample. The distillation flask containing the active solvent is filled with the thimble. A siphon aspirates the solution as it reaches overflow levels. In transferring the solution to the distillation flask, the siphon is used. The solution transports the extracts into the bulk liquid. Once the solute is retained in the distillation flask, the solvent returns to the solid bed of the plant. Repetition of this step is necessary till the extraction is complete.

Maceration: Maceration is a multi-step process for smallscale extractions. To ensure proper solvent mixing, plant materials are ground into fine particles. Maceration involves the addition of a solvent, called a menstruum, to a sealed vessel containing plant material. Once the liquid is drained, the remaining solid residue or marc, is pressed to extract more significant volumes of residual solutions. Filtration is then performed to remove impurities from the strained and pressed liquids. Intermittent shaking during maceration enhances diffusion and helps remove condensed solutions from the sample’s surface, thereby increasing the extraction yield.

Potential Health Benefits of Peanut Oil with Plant Extracts

Incorporating plant extracts into PO positively affects cardiovascular health, which is a significant potential benefit. PO with plant extracts may contain phytochemicals, including phenolic compounds and carotenoids, which may effectively combat cancer. Several of these compounds may be helpful in the prevention of cancer because of their antioxidant properties and anti-inflammatory, enhance brain function and decrease the likelihood of neurodegenerative disorders like Alzheimer’s. According to Kopustinskiene et al., bioactive compounds in plant extracts could provide neuro-protective properties.

Future Directions in the Use of Plant Extracts in Peanut Oil

There is potential for developing more efficient and sustainable methods for extracting plant extracts. Solvent extraction, for instance, can be time-consuming, costly and environmentally harmful. Several highly efficient and environmentally friendly extraction techniques are being investigated, including ultrasonic-assisted and supercritical fluid extraction. New plant extracts with unique bioactive compounds may also be identified and utilized with potential health benefits. Various extracts’ antioxidant and antiinflammatory properties are currently being studied in this area. Extracts from plants in oils can potentially affect the oil’s flavour and aroma. Additional research is required to identify plant extracts with nutritional and antioxidant properties that do not alter the sensory qualities of oils. Therefore, the extraction of plant extracts and their incorporation into the final product must be optimized to ensure product quality.

Conclusion

Plant extracts are highly effective in increasing peanut oil’s antioxidant activity and nutritional value. Plants extracts can be incorporated into peanut oil, which increases its bioactive content, such as polyphenols, tocopherols and carotenoids, and enhances its stability under oxidative stress. Moreover, peanut oil with plant extracts may possess potential health benefits, such as improved cardiovascular health, a decreased risk of cancer and improved brain function. Although significant progress has been made, several challenges still need to address. These challenges include the discovery and utilization of novel plant extracts, the advancement of extraction procedures that are both efficient and environmentally sustainable, and the optimization of the incorporation process to achieve product stability and desirable sensory attributes in the final product. Future research is necessary to tackle these challenges and delve deeper into the potential health advantages of incorporating plant extracts into peanut oil.

References

- Abidi SL (2001) Chromatographic analysis of plant sterols in foods and vegetable oils. J Chromatogr A. 935(1-2):173-201.

[Crossref] [Google Scholar] [PubMed]

- Adegoke GO, Gopala Krishna AG (1998) Extraction and identification of antioxidants from the spice Aframomum danielli. J Am Oil Chem Soc. 75(8):1047-1052.

[Google Scholar]

- Akhtar S, Khalid N, Ahmed I, Shahzad A, Suleria HA (2014) Physicochemical characteristics, functional properties, and nutritional benefits of peanut oil: A review. Crit Rev Food Sci Nutr. 54(12):1562-1575.

[Crossref] [Google Scholar] [PubMed]

- Alexandre EM, Araújo P, Duarte MF, de Freitas V, Pintado M, et al. (2017) Experimental design, modeling, and optimization of high-pressure-assisted extraction of bioactive compounds from pomegranate peel. Food Bioprocess Technol. 10:886-900.

[Google Scholar]

- Altemimi A, Lakhssassi N, Baharlouei A, Watson DG, Lightfoot DA (2017) Phytochemicals: Extraction, isolation, and identification of bioactive compounds from plant extracts. Plants. 6(4):42.

[Crossref] [Google Scholar] [PubMed]

- Anokwuru CP, Anyasor GN, Ajibaye O, Fakoya O, Okebugwu P (2011) Effect of extraction solvents on phenolic, flavonoid and antioxidant activities of three Nigerian medicinal plants. Nat Sci. 9(7):53-61.

[Google Scholar]

- Arya SS, Salve AR, Chauhan S (2016) Peanuts as functional food: a review. J Food Sci Technol. 53:31-41.

[Crossref] [Google Scholar] [PubMed]

- Atalay AB, Ä°nanc AL (2018) Stability of sunflower oil enriched with olive phenolics in deep frying condition. GaziosmanpaÅ?a Univ J Agric Fac. 35(2):152–163.

[Google Scholar]

- Awad AB, Chan KC, Downie AC, Fink CS (2000) Peanuts as a source of β-sitosterol, a sterol with anticancer properties. Nutr Cancer. 36(2):238–241.

[Crossref] [Google Scholar] [PubMed]

- Azadmard-Damirchi S (2010) Review of the use of phytosterols as a detection tool for adulteration of olive oil with hazelnut oil. Food Addit Contam Part A Chem Anal Control Expo Risk Assess. 27(1):1–10.

[Crossref] [Google Scholar] [PubMed]

- Azmir J, Zaidul ISM, Rahman MM, Sharif KM, Mohamed A, et al. (2013) Techniques for extraction of bioactive compounds from plant materials: A review. J Food Eng. 117(4):426–436.

[Google Scholar]

- Ballard TS, Mallikarjunan P, Zhou K, O’Keefe S (2010) Microwave-assisted extraction of phenolic antioxidant compounds from peanut skins. Food Chem. 120(4):1185–1192.

[Google Scholar]

- Banerjee J, Singh R, Vijayaraghavan R, MacFarlane D, Patti AF, et al. (2017) Bioactives from fruit processing wastes: Green approaches to valuable chemicals. Food Chem. 225:10–22.

[Crossref] [Google Scholar] [PubMed]

- Barba FJ, Grimi N, Vorobiev E (2015) New approaches for the use of non-conventional cell disruption technologies to extract potential food additives and nutraceuticals from microalgae. Food Eng Rev. 7:45–62.

[Google Scholar]

- Barba FJ, Terefe NS, Buckow R, Knorr D, Orlien V (2015) New opportunities and perspectives of high pressure treatment to improve health and safety attributes of foods: A review. Food Res Int. 2015;77:725–742.

[Google Scholar]

- Barba FJ, Zhu Z, Koubaa M, Sant’Ana AS, Orlien V (2016) Green alternative methods for the extraction of antioxidant bioactive compounds from winery wastes and by-products: A review. Trends Food Sci Technol. 49:96–109.

[Google Scholar]

- Blasi F, Cossignani L (2020) An overview of natural extracts with antioxidant activity for the improvement of the oxidative stability and shelf life of edible oils. Processes. 8(956):1–15.

[Google Scholar]

- Blasi F, Rocchetti G, Montesano D, Lucini L, Chiodelli G, et al (2018) Changes in extra-virgin olive oil added with Lycium barbarum L. carotenoids during frying: Chemical analyses and metabolomic approach. Food Res Int. 240:429–36.

[Crossref] [Google Scholar] [PubMed]

- Boroski M, Aguiar AC, Rotta EM, Bonafe EG, Valderrama P, et al. (2018) Antioxidant activity of herbs and extracted phenolics from oregano in canola oil. Int Food Res J. 2018;25(6):2444–2452.

[Google Scholar]

- Cádiz-Gurrea MDLL, Borrás-Linares I, Lozano-Sánchez J, Joven J, Fernández-Arroyo S, et al. (2017) Cocoa and grape seed byproducts as a source of antioxidant and anti-inflammatory proanthocyanidins. Int J Mol Sci. 18(2):376.

[Crossref] [Google Scholar] [PubMed]

Citation: Sarpong P (2025) Use of Plant Extracts in Peanut Oil to Improve Nutritional Value and Antioxidant Activity: A Review.

Br J Res. 12:119.

Copyright: © 2025 Sarpong P. This is an open-access article distributed under the terms of the Creative Commons Attribution

License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source

are credited.